The length was the rough opening minus 1/4" minus the thickness of two 2x4's. The rail ends and sill ends were mitered to 22.5 degrees. I measured the rough opening and subtracted 1/4" from the height and width. I started by removing the four stud ties in the first picture. I wanted extra ventilation for the summer and wanted it to be completely closed on very cold days.Īt this point, I needed a door. The last picture is a view from the inside with the window closed. I discovered this was happening after I installed them. The second to last picture shows a small 45 degree chamfer that I cut so the window wouldn't hang up on the sill when opening. The rails are just plain 90 degree pieces of 2x2 cut to length. The vertical pieces, or stiles, are the pieces of 2x2 ripped to 22.5 degrees.

#Small octagon windows wood windows#

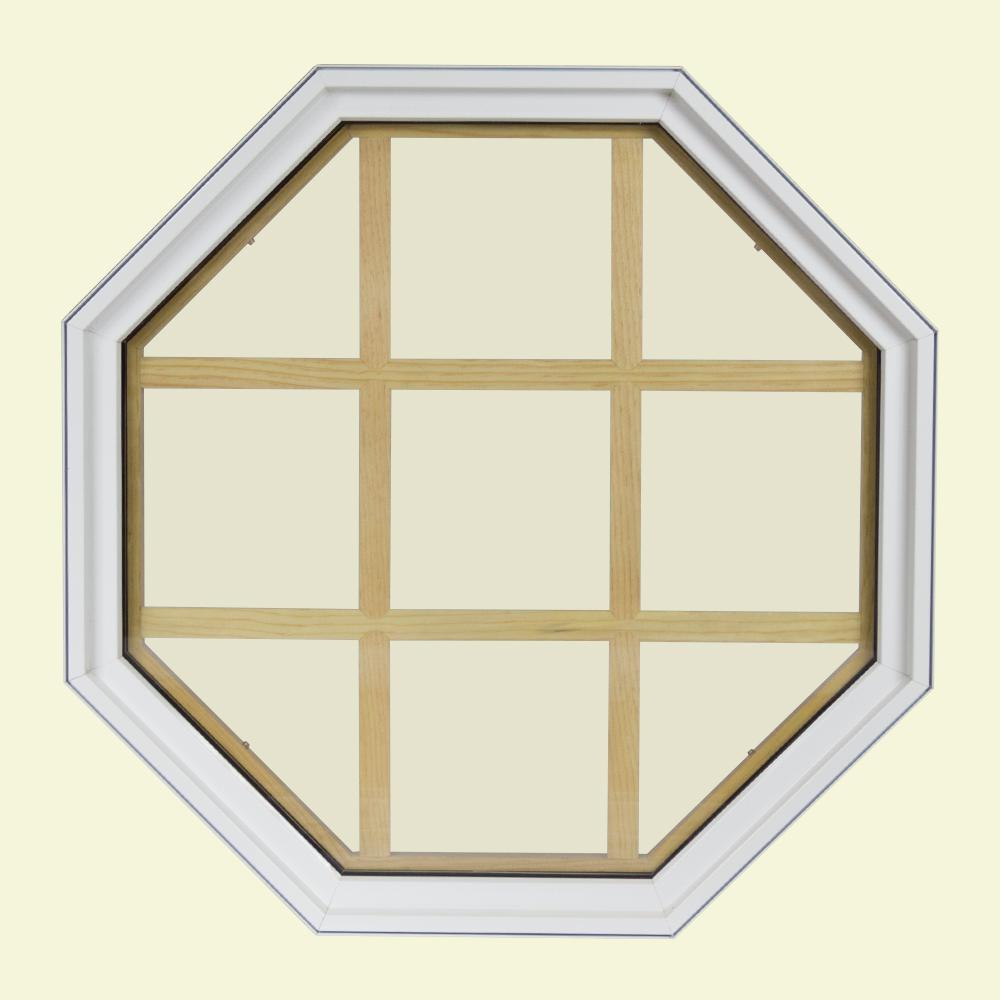

The windows are constructed from trim pieces that were ripped to 22.5 degrees to fit in the openings. The last pictures are views from the outside and two inside.

Next I mitered the edges to 22.5 degrees to fit in between the rafters. I set the table saw to rip a 30 degree chamfered edge so when the roofing substrate was installed, it would sit flush with the rafters and blocking with minimal air gaps. First I measured the distance between the rafters. I need to seal the greenhouse to the outside air. I then set my table saw blade to 22.5 degrees and ripped that angle so the cleat would sit flush with the studs and remain parallel with each of the outer walls for easy mounting of the the window glazing and the lower panels. Again, the edges were mitered to 22.5 degrees.įor the vertical cleats, I used the cut-offs from ripping 2x4's from the 2圆's. I used a small carpenter's square to lay out pencil lines for the location of the cleats. They are set back 1" from the edge of the sills to account for the horizontal closure strips for the polycarbonate and the depth of the panels. I planed the paint off of all the 2"x2" deck rail spindles which gave a finished dimension of 1 3/8" x 1 3/8". The cleats for the window sills, base and wall caps are 26" wide x 1 3/8" x 1 3/8". So, I reverse designed the whole structure around the 26" width for the windows and decided on the height based upon the common lengths. The problem is that it only comes in 26" wide panels, which turns out that they are only 25 3/4". I liked the corrugated polycarbonate for windows or glazing. I didn't state it earlier, but I did some research on materials used for greenhouses. Next is the trim/cleats for mounting windows and lower wall panels. I then cut out eight more pieces, the same as the base, and fastened them to the top of the studs for wall caps using the same stud ties used at the base.

One side of the octagon was left open for a rough opening for a door. Since you lose some of the width or length from the kerf on a saw blade, I figured I would cut the dimensions down to have a perfect fit. I wanted to maximize the use of a commom 4' x 8' exterior siding panel. The sills were set 23.5" from the top of the base plate. Each side of the sills needed to be mitered to 22.5 degrees. Once all eight were in place, I cut seven sills. I used Simpson Strong Ties to fasten the king studs to the base on a 22.5 degree angle. The King studs are 72", the base pieces are 28 1/2", and the sills are 27". The cut-offs come in handy later for the cleats and trim work. The second picture is the same base depicted above after a few minutes with a belt sander. Most of the knot holes had rotted, but the wood was still in great shape and structurally sound beneath the paint and the superficial weathering. I trashed out a set of planer blades removing most of the paint and some of the raised grain from weathering. The first picture is a load of recycled Redwood with old red paint on it that used to be my bosses front deck. This allowed me to backfill the original foundation and leave the blocks above grade so I wouldn't have wood to ground contact. So, I built a form the shape of each side of the octagon and made eight trapezoids which I later fixed in place with mortar. I wanted my base to outlast pressure treated wood and be heavier. I see that most people just build theirs on pressure treated 4x4's. I was not satisfied with the size or weight, because I live in a high-wind area. In hindsight, I should have built the form deeper.

The high spots that were sticking out of the water were easily leveled with the back side of a rake. I had previously flooded the hole to soften the clay to do a final leveling. I pounded the stakes in partially, then placed the level across in multiple positions and drove the high spots down with a mallet. The string in the first picture is the north/south line.

Before placing stakes to secure the form, I determined true north/south so one wall would face perpendicular to the north/south line.

0 kommentar(er)

0 kommentar(er)